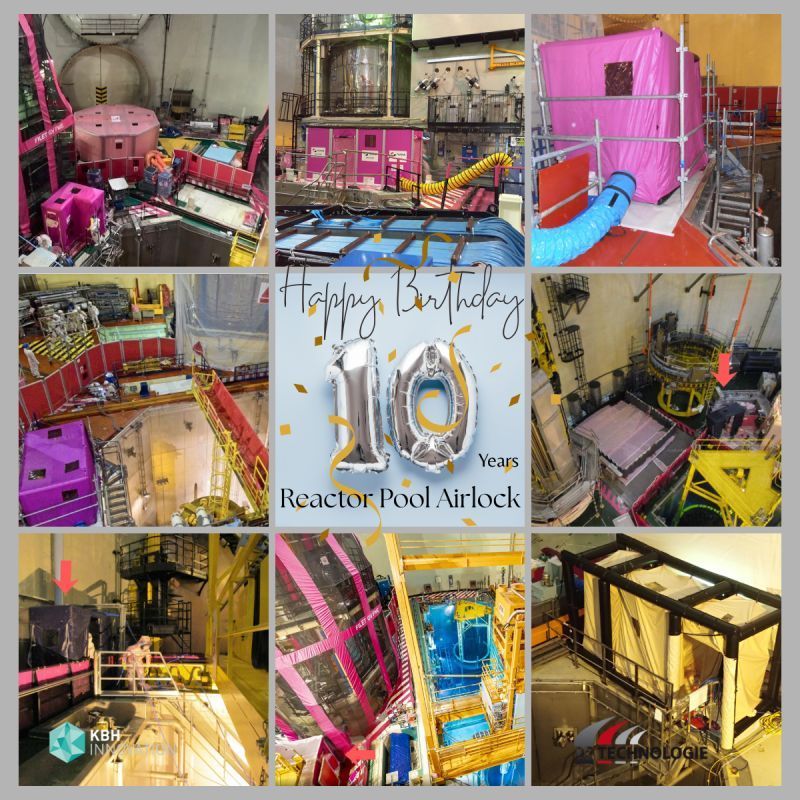

PROJECT RJH "EXPERIMENTAL MATERIAL TEST REACTOR" JULES HOROWITZ

We were happy to support the RJH employees in their project and together with the team we looked for improvements and new solutions so that the work could continue efficiently and safely.

The reactor, which is still under development, was from above:

⬆️ - covered with a sluice

Laterally:

➡️ - equipped with a clean room lock.

The lock has been adjusted, improved and further adapted several times.

⬇️ - An additional floor has now been added.

Thank you for the trust!!!

FOLLOW OR CONTACT US

At nuclear sites, preventing hashtag#FME risks (foreign material exclusion) is a critical priority. Even a single foreign object introduced into sensitive equipment can compromise safety, disrupt operations, or lead to significant intervention costs. That’s why we support maintenance teams with solutions tailored to each environment, including: 👉 protective nets to secure work areas 👉 shutters to isolate critical access points 👉 custom-made soft protective covers to prevent the intrusion of particles or tools Each solution is designed to reduce FME risk, simplify inspections, and preserve the integrity of the equipment

We’re kicking off the new year… and celebrating 10 years of our first pneumatic BR airlock! 🎈 The civilian nuclear industry is often seen as a space resistant to innovation. Yet experience shows: when there’s an opportunity to do things better — whether improving safety or operational performance — the teams on the ground are always open to it. The pneumatic airlock for the reactor building (BR), developed for and with EDF, is a perfect example. Ten years ago, it was designed, tested, and first deployed at the Saint-Laurent site in close collaboration with the then-MEEI service under Lara Baudin’s leadership. This year, it celebrates a decade of successful operation in the controlled zone. Why has it lasted so long? Because it fully meets real-world requirements: Rapid installation and quick deployment Low calorific value and reduced fire load Flexible structure that helps reduce seismic risks A decade later, what was once an innovation has become a widely adopted solution: it is now part of the national contract and deployed across all sites. A great example of what truly works: listen to real operational needs, innovate, and implement consistently. So, in that spirit: Happy B-Day to youuuu… 🎉

We received a wonderful surprise in the mail! Dear Nuklearforum Schweiz – Swiss Nuclear Forum team, thank you so much for the neck warmer and the thoughtful card. Of course, we are ready and already committed to actively shaping a sustainable energy future together with all stakeholders. We are excited to get involved and look forward to any exchange and collaboration. We wish you all relaxing holidays and a fantastic start to the new year. #GOgreenGOnuclear

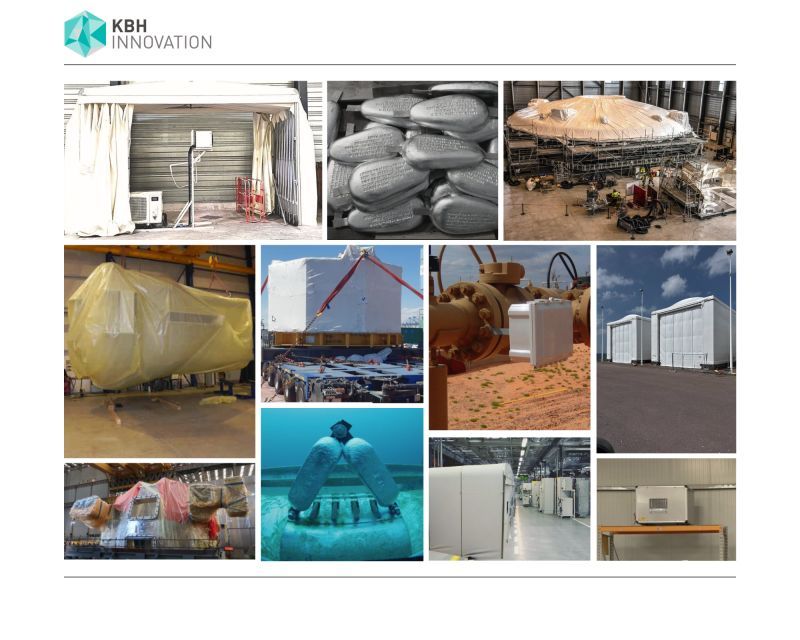

Even large equipment can be easily protected from storage damage, while simplifying storage processes significantly. Take, for example, this implementation for storing steam generators. Each generator is protected at the base with a VCI film cover, and each also includes a diffuser inside. This allows the equipment to be safely stored for months without risk of damage. Do you have an idea how we could support you? Get in touch with us

Flexible Industrial Tunnels for Safe and Efficient Maintenance This custom-built enclosure was integrated directly into a maintenance hall, making it ideal for work on large machinery components, including welding operations. The structure is fire-rated A2–M0, meeting the highest safety standards. Foldable and modular: The tunnel can be quickly collapsed, allowing machinery parts to be exchanged by crane without a complete rebuild — saving significant setup time. A true all-rounder: these tunnels are suitable for containment operations, storage, restoration work, garage solutions, handling areas, magnetic inspection applications, and many other industrial uses. Interested in flexible solutions for maintenance, protection, or enclosures? We’re here to help.

🚨 Special Forces rightly hold a vital place in our society We are proud to equip the existing headquarters of EDF’s Force d’Action Rapide du Nucléaire with a new, rapidly deployable extension — pneumatic, mobile, and highly efficient. Our decontamination airlock enables teams to quickly decontaminate affected individuals and provide first aid, allowing rescue operations to be carried out safely and without delay. Key benefits at a glance: Rapid deployment: Pneumatic and mobile — ready for immediate use Safety: Decontamination airlock for fast on-site decontamination and first aid Efficiency: Streamlined workflows for rescue teams Flexibility: Seamless integration into existing headquarters Innovation: Advanced technology designed for demanding missions

We are delighted to announce that we have won a tender from the French Ministry of the Armed Forces. Alongside our long-standing expertise in industrial risk control, we now have the honor of manufacturing retention basins. This ambitious, long-term project opens up new opportunities in a sector that is both highly demanding and extremely exciting. It requires rigorous coordination, smooth communication, and the full commitment of our teams — and we are ready. 💪 A big thank you to all our team members for their energy and dedication, who believed in this project from the very beginning and supported it with determination, hard work, and outstanding perseverance. Thanks to them, this challenge has become a success. 🙏 We also thank our partners for their trust and valuable support throughout the process. 🤝 And finally, our sincere thanks to the French Armed Forces for placing their trust in a French company to deliver this ambitious project. 🟦 ⬜ 🟥 A new chapter is being written — full of opportunities, challenges, and great achievements yet to come.

Corrosion… a never-ending challenge. KBH Innovation supports industrial companies every day in protecting their sensitive assets and preventing premature degradation. Among the many technologies available to combat corrosion and oxidation, we offer a comprehensive portfolio of solutions: Climate-controlled enclosures Air treatment and ventilation systems Volatile corrosion inhibitors (VCI) Protective gas packaging Sacrificial anodes Cathodic protection systems Biocide treatment (MIC) In practice, the most effective protection is often achieved by combining several of these approaches, creating a solution precisely tailored to our customers’ operational requirements. We are always available to support you with studies, analyses, or expert consulting to define the most suitable protection strategy for your assets.

For the EDF (UK) nuclear power plant at Hinkley Point, we worked with our partner DR Technologie to manufacture a total of 250 preservation bags, specifically designed to meet the demands of a large-scale nuclear project. These bags are used to protect sensitive components during storage, transport and installation. Thanks to their robust, custom-engineered design, they provide a reliable barrier against moisture, dust, contamination and environmental influences — a key contribution to safety, quality and long-term plant availability.

Until now, many were familiar only with the panel-based version. Here is the pneumatic hot-spot airlock: Lightweight and quick to install directly on site Space-saving in storage thanks to the absence of a rigid structure Ideal for flexible operations and rapid reconfiguration Fire-rated M0 … Containment for welding, brazing, grinding and similar hot works — no longer a challenge. Where efficiency meets pneumatic flexibility. Feel free to get in touch to learn more.

🎥 A look behind the scenes: This video from an EDF nuclear power plant shows the preparations for maintenance work and the loading of new fuel assemblies — impressively precise, even two years later. Several of our technical solutions are in use, developed to make operations safer, more efficient, and more flexible. You can also see the modular panels presented in the previous post, being transported to their point of use on a trolley and assembled on site. The protective nets on the steam generators and the pneumatic airlock are clearly visible as well. We are proud that our containment and protection systems contribute to the smooth and safe execution of these highly sensitive operations. 📌 For the safe and efficient execution of your work — feel free to contact us.

📌 Do you know this situation? In many projects, every minute counts. Efficiency, safety, and flexibility are critical — that’s exactly what these modular containment systems were designed for. Built to customer specifications, they are delivered mobile on a trolley and can be deployed on site within minutes or stored just as easily. Their reusable, modular design allows for simple adaptations and has already proven itself at numerous sites — with demand continuing to grow. Efficient and time-saving – quick assembly and rapid readiness for use Reusable and expandable – a sustainable solution for changing requirements Repairable and durable – individual modules can be easily replaced Optional air system – adaptable to specific safety requirements Decontaminable – suitable for safe repeated use Hot-spot compatible and fire-rated – tested for demanding environments … Whether for maintenance work, temporary separations, or complex containment zones, this technical solution grows with the task. Feel free to contact us if you have any questions about your project.