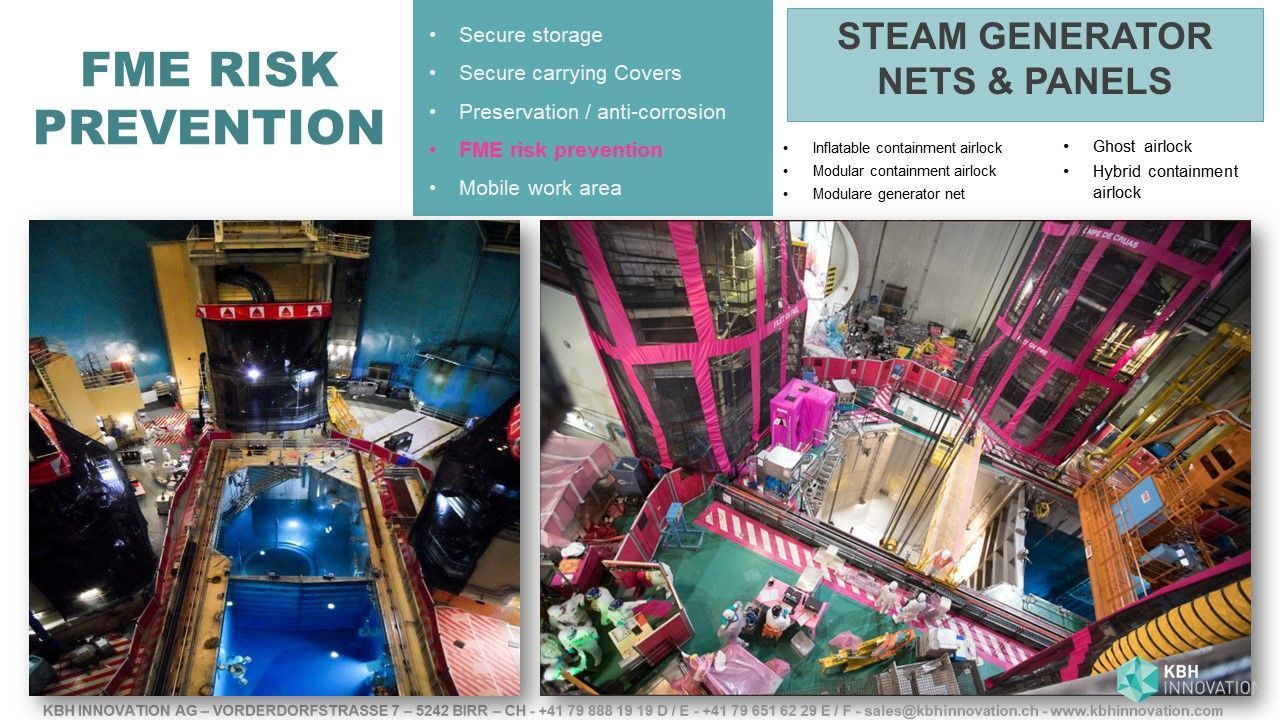

STEAM GENERATOR NETS & PANELS

💡 Part of a group with a difficult work area?

Especially in the nuclear industry, and also in other industrial sectors, there are many constraints in the daily work that make many activities and operations more complicated. This does not have to be, with a good teamwork, with all parties together, through common discussions, the most efficient and practical solutions are created, which can be easily integrated into the work processes and also meet all the requirements. Those of the supervisors, technical group and those of the working teams.

In order to support the working collective in the maintenance work, we always put our heads together to find the most suitable solution. This has resulted in various protector solutions for steam generators. All of them are designed in such a way that they consist of individual parts that are easier to install and therefore easier to handle, i.e. more efficient. If a part is defective, it can be easily replaced. FME compatible solutions like these are always developed together with the customer and the end user, so that we can plan and ensure all requirements and usage compatibility in the development project.

We are ready for your needs! Contact us....

FOLLOW OR CONTACT US

The tool shown is a lateral protective cover for manholes – specifically designed to safeguard manhole seals. The tool features strong integrated magnets that securely attach it to the manhole wall. Additional holes around the tool allow continued use of existing bolts for fixation. The construction consists of two membrane layers, providing enhanced safety and stability. It has already been deployed, for example, at the EPR Flamanville 3 site. The internal foam lining adds extra protection and safety for surrounding equipment. A fascinating example of how smart design details contribute to safety, efficiency, and protection in everyday operations.

Ready in minutes – when every second counts. Our mobile rapid deployment bases are designed to support emergency teams in any situation – from medical incidents and chemical accidents to disaster response and special operations. Key advantages at a glance: Quick setup – operational within minutes Modular design – easily expandable and adaptable High safety – robust, weather- and wind-resistant construction Customizable equipment Easy transport – comes with a carry bag Cost and time efficiency – reduced staffing and installation effort Whether for fire services, military, police, or medical teams – our rapid deployment bases ensure maximum flexibility and readiness, exactly where it matters most. “Speed that saves lives.”

In sensitive environments, every detail matters to prevent foreign object intrusion. The FME umbrella is a simple yet effective solution to protect critical areas during overhead operations. Blocks falling dust, tools, and debris Lightweight, quick to install, and reusable Secures operations and preserves equipment integrity A small action – with a big impact on prevention!

Flexible shielding – the right structure for every area Workers already using the WM0 hot-spot airlock often ask if other structures are available. 👉 Absolutely – here they are: pneumatic, foldable, and/or modular. Compact. Flexible. Quick to install. Fire protection class A2-S1-D0 A solution that adapts to your process. Custom-made, tailored precisely to your needs.

A reusable and adaptable airlock Our inflatable airlocks are built to last! With a repairable structure and removable, interchangeable panels, they adapt perfectly to on-site constraints and the demanding conditions of industrial environments. The advantage of in-house production – beyond responsiveness and flexibility – is our ability to incorporate our partners’ requirements in real time. This naturally includes reusability and a high degree of reparability.

Flexible cleanroom airlocks – tailored to your requirements We design and manufacture cleanroom airlocks and modular extensions that adapt seamlessly to your processes and spatial conditions. ✔️ Foldable ✔️ Equipped with mobile panels ✔️ With or without air filtration system ✔️ Optional integrated gloves ✔️ ... Whether for laboratories, production environments, or sensitive assembly areas – our airlocks are custom-built to meet your exact needs.

Protective Covers for Every Challenge In a world where safety and protection are top priorities, we offer specialized covers for a wide range of applications. Our solutions ensure: Environmental Protection – Ideal for use in harsh outdoor conditions, shielding your equipment from wind, rain, and UV exposure. Dual-Sided Contamination Control – Effectively protect your equipment from harmful substances, dust, and dirt — or prevent your tools from contaminating the environment, which could jeopardize operations. Chemical Resistance – Our durable covers are specifically designed for environments where contact with aggressive chemicals is unavoidable. Whether in industrial settings, mechanical engineering, or laboratory environments – we provide custom solutions that reliably protect your equipment and extend its lifespan. 👉 Let us know how we can support your specific requirements!

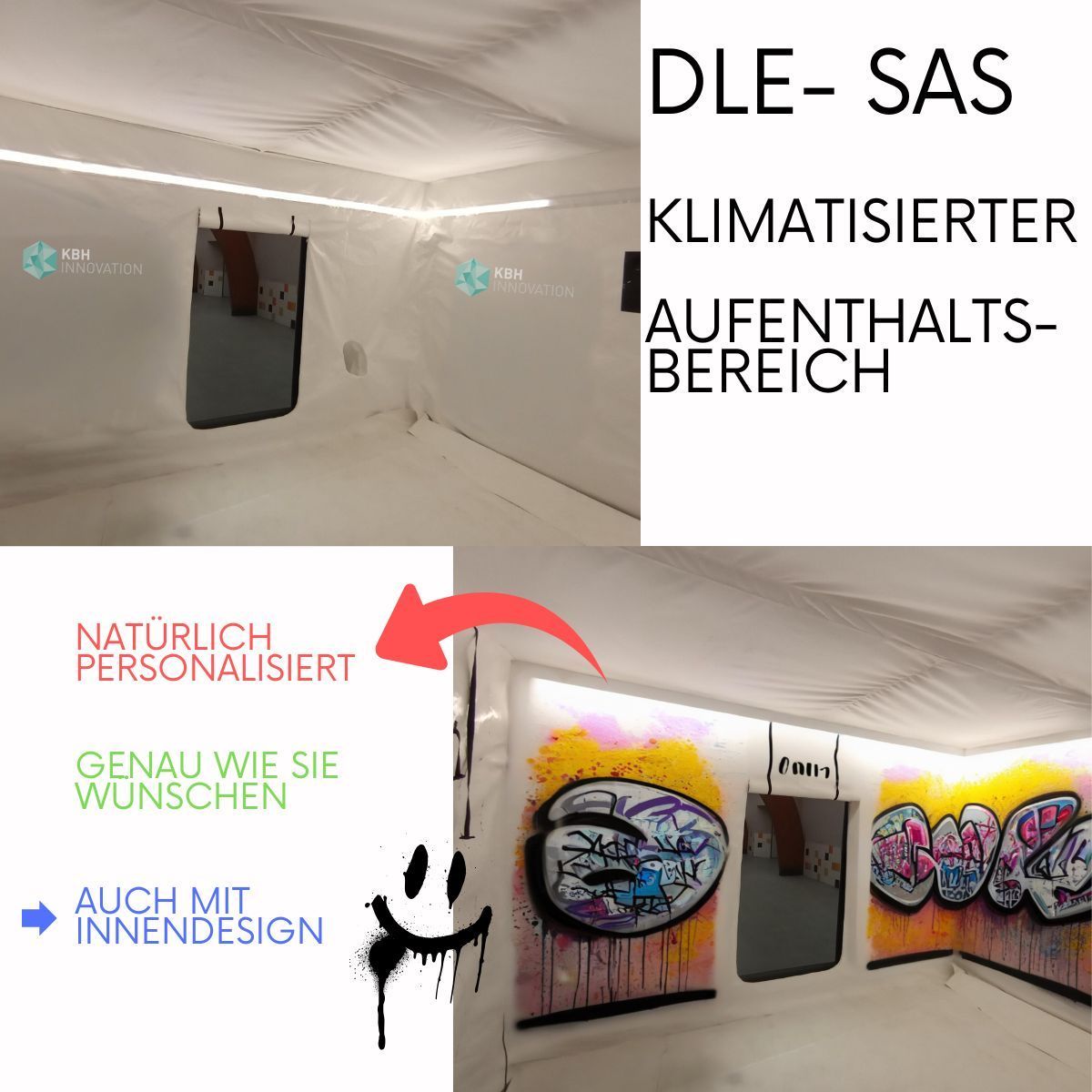

Our air-conditioned DLE unit is the ideal break area for work in high-temperature zones – flexible for both indoor and outdoor use. Designed for your team to work more efficiently, comfortably, and safely. And the best part? We personalize the unit according to your wishes – even with custom wall prints. All produced in-house within the EU. Got questions? Feel free to reach out – we’re happy to help!

TThe rugged all-rounder for countless applications! Sometimes, you just need a solution that’s perfectly tailored to your professional needs. That’s exactly what our custom-designed tunnels offer! Durable, robust, and flexible, they adapt to virtually any use case — whether in gastronomy, cleanroom airlocks, decontamination zones, hot-spot operations, access tunnels, or magnetic particle inspection. Almost anything is possible! ☝ And the best part: These tunnels can be folded and connected to one another. This allows large tools to be easily lifted in by crane for maintenance work. A true multi-talent — indispensable across many industries! 👉 Looking for a custom solution that does it all? You’ve come to the right place!

When the heat hits, improvisation begins… 🥵 A kiddie pool on the construction site? Charming – but not exactly practical. 😅 Although… we do offer containment basins 😉 👉 Still, we prefer our mobile, air-conditioned recovery unit – for real cooling, without soaking your helmet, vest, or trousers. WHY? ✅ Proven reduction in heat-related downtime ✅ Improved focus after breaks ✅ Long-term health protection for your team ✅ ... And the best part: Our systems are mobile, durable, reusable, and always ready for action. Got your attention? Reach out to us – we’re happy to help!

💡 Safe operations in sensitive environments — with a system that works This decontamination glove box was specifically designed for maintenance and decontamination tasks in controlled areas. Available in various configurations, it’s built to support teams efficiently and effectively. ✅ Custom-made – precisely tailored to your needs ✅ Pneumatic – for flexible and rapid deployment ✅ Reusable & decontaminable – for sustainable use ✅ Filter hose opening – ensures safe air exchange ✅ FME-compatible – ideal for nuclear and critical environments ✅ Compact, lightweight & thoughtfully engineered – suitable for any maintenance scenario Whether for outage operations, contamination points, or preventive measures: This box protects what matters most — personnel, processes, time, and the environment. 👉 Interested in a demo or more technical details? We’d love to hear from you! 💬

Do you work under extreme conditions? Six hours in a protective suit? 40 °C under the blazing sun? No place to rest — or a long walk to get there? In precisely these environments, effective recovery for you and your teams is absolutely essential. Whether on nuclear power plants or complex infrastructure projects, the requirements are clear: ✅ rapid setup ✅ simple, autonomous use ✅ easy transport ✅ proven effectiveness ✅ adaptable to demanding environments Our modular rest areas are designed specifically for these challenges: ➔ climate control suitable for tropical conditions ➔ self-sufficient solar-powered energy supply ➔ setup in minutes — no technician required ➔ mobile on a compact trolley For optimal protection — even under extreme conditions. 👇 Curious about real-life experiences from the field? C ontact us directly.